Product features:

- Physical properties:

- Good mechanical properties

- Good high and low temperature resistance

- Good flame retardancy

- Good corrosion resistance

- Good weather resistance

- Good lubricity (low friction coefficient)

- Excellent radiation resistance

- Good bending resistance

- Good anti-adhesion performance

- Electrical properties:

- Good electrical insulation performance

- High resistivity

- Processing performance:

- Use semi-extrusion processing

- Good wire harness processing performance

- Good compatibility during wire harness processing

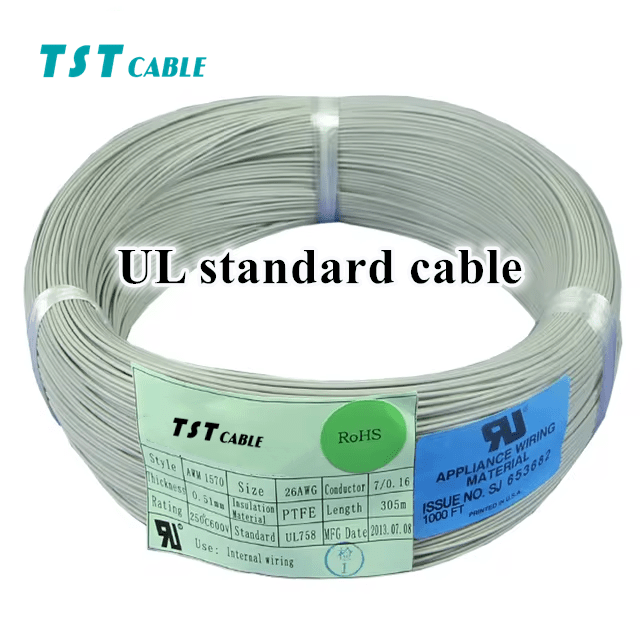

- Designed according to UL standards

- Environmental protection:

- Comply with ROHS/REACH

- Non-toxic

- Application:

Electrical wire, used in places where the temperature does not exceed 250 degrees.

- Reference standards:

UL758-2010, UL1581-2009, UL1570

- Structural description:

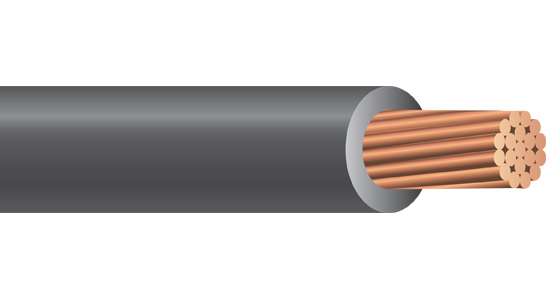

Conductor structure: nickel-plated copper conductor

Insulation material: PTFE polytetrafluoroethylene insulation

Conductor temperature: PTFE insulated wire not exceeding 250℃

Rated temperature: 250℃

Rated voltage: 600V

| model |

Specification

AWG |

Conductor structure (pieces/mm) ±0.005mm |

Conductor resistance 20℃ (Q/Km) |

Conductor diameter (mm) |

Insulation thickness (mm) |

Finished outer diameter (mm) |

||

| Average value | Minimum value | Average value | Tolerance | |||||

| 1570 | 6 | 7/38/0.254 | 1.403 | 5.43 | 0.76 | 0.69 | 6.95 | ±0.15 |

| 8 | 7/19/0.287 | 2.23 | 4.35 | 0.76 | 0.69 | 5.87 | 10.15 | |

| 10 | 37/0.42 | 3.54 | 2.94 | 0.76 | 0.69 | 4.46 | +0.15 | |

| 12 | 37/0.374 | 5.64 | 2.62 | 0.50 | 0.46 | 4.14 | ±0.15 | |

| 14 | 19/0.361 | 8.96 | 1.82 | 0.50 | 0.46 | 2.82 | ±0.10 | |

| 16 | 19/0.287 | 14.60 | 1.45 | 0.50 | 0.46 | 2.45 | ±0.10 | |

| 18 | 19/0.235 | 23.20 | 1.18 | 0.50 | 0.46 | 2.18 | ±0.10 | |

| 20 | 19/0.19 | 36.70 | 0.95 | 0.50 | 0.46 | 1.95 | +0.10 | |

| 22 | 19/0.15 | 59.40 | 0.76 | 0.50 | 0.46 | 1.76 | ±0.10 | |

| 24 | 7/0.20 | 94.20 | 0.61 | 0.50 | 0.46 | 1.61 | ±0.10 | |

| Illustrate:In addition to the products of the above specifications, TSTCABLES can also customize other specifications according to your needs. Welcome to email consultation and receive free samples. | ||||||||

Also available in:

English

WHY CHOOSE TST

19 quality tests before cable shipment

R&D personnel account for 42% of the company’s headcount

Support all kinds of customization, free sampling

10,000 ㎡ factory, annual production capacity of 2,000,000 meters