- Home

- /

- Airborne Air Conditioning

Application of Cables in Aircraft Air Conditioning Systems

1. Scene Introduction

With the increasing sophistication of aviation technology, aircraft air-conditioning system, as the core system to ensure the comfort and safety of the cabin environment, has received extensive attention for its operational stability and reliability. As an important part of the aircraft air conditioning system, the quality and performance of cables are directly related to the overall performance of the system. Therefore, cable solutions designed specifically for aircraft air conditioning systems are particularly important.

2. The pain point analysis

Cables for aircraft air conditioning systems face multiple challenges. The complex environment in the cabin, including high and low temperature variations, strong vibration and electromagnetic interference, puts stringent requirements on the performance of cables. In addition, air conditioning systems require extremely high transmission speeds and stability of cables to achieve precise control of temperature, humidity and other parameters. Therefore, traditional cables are often difficult to meet these complex and demanding applications.

3.The aircraft air conditioning system on the cable requirements

Aircraft air conditioning system cables need to meet the following key requirements:

Electrical performance: excellent conductivity to ensure fast and stable signal transmission.

Environmental adaptability: high and low temperature resistance, anti-vibration, anti-electromagnetic interference, to adapt to the complex environment in the cabin.

Fire-resistant, low-smoke halogen-free flame retardant, safety: flame retardant, low-smoke, non-toxic, to ensure the safety performance of the cable in emergency situations.

Lightweight: the cable is lightweight and has a small space in order to reduce the impact on the overall weight of the aircraft.

4. The certification standards

Aircraft cabin broadcasting system cables must comply with the certification standards in the international aviation field, such as the certification of the U.S. Federal Aviation Administration (FAA), the European Aviation Safety Agency (EASA) certification, etc. TICW/06-2009, GB/T19666-2008, EN50200-2015, EN50264, EN50306, EN50382, etc.,. These standards have strict regulations on the electrical performance, environmental adaptability and safety of the cables to ensure that the quality and performance of the cables reach the aviation level.

5.Product Selection

For the special needs of aircraft air conditioning system, TST CABLES recommends the following cable products:

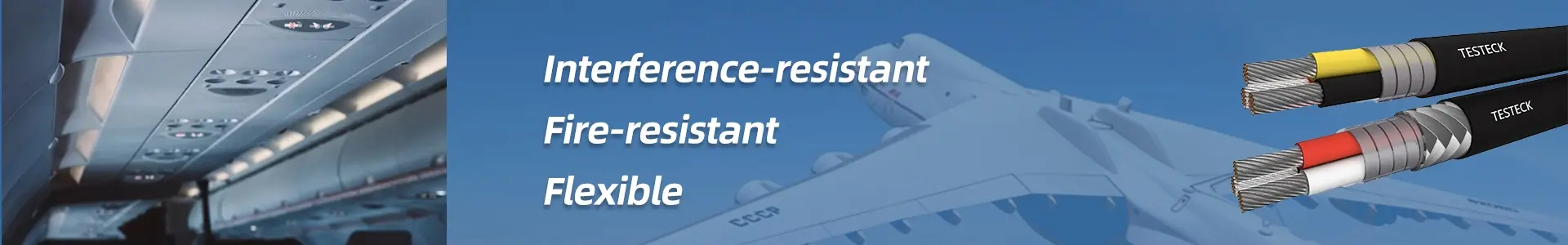

Shielded Cables: Shielding prevents electromagnetic interference and ensures reliable signal transmission in the presence of other electrical components.

High Temperature Cables: These cables are designed to withstand extreme temperature ranges, ensuring uninterrupted performance in both high and low temperature environments.

Fire-resistant cables: Fire-resistant cables are specifically designed to prevent the spread of fire, providing additional safety for aircraft air conditioning systems.

Flexible cables: Flexibility is critical in aircraft applications, allowing for easy installation and wiring in limited spaces. Flexible cables ensure efficient and reliable connections for air conditioning systems.

During the selection process, TST CABLES will also consider the cable cross-section, length, connection method and other factors according to specific application scenarios and needs, in order to ensure that the cable is a perfect match for the aircraft air conditioning system.

6. Product Characteristics

This cable solution has the following outstanding characteristics:

Excellent electrical performance: high purity copper conductor is used to ensure the accuracy and stability of signal transmission.

Strong environmental adaptability: The cable sheath is made of special materials with excellent resistance to high and low temperatures, vibration and electromagnetic interference.

Flame retardant and low smoke: the cable complies with aviation flame retardant standards, effectively reducing the risk of fire.

Lightweight and easy to install: the cable has a compact design and is lightweight, making it easy to install and wire inside the airplane.

Recommended Products

Airborne air conditioning system cables have fast signal transmission and strong anti-interference ability. They are key components on the aircraft and are responsible for transmitting power, control signals and data between air conditioning units, temperature sensors and control modules.

7.Technical Tests

To ensure that the quality and performance of the cables meet the requirements of aircraft air-conditioning systems, TST CABLES conducts a series of rigorous technical tests. These tests include electrical performance tests, environmental adaptability tests, flame retardant performance tests, etc. to ensure that the cable meets or exceeds international aviation standards in all performance indicators.

8. Cable laying installation and commissioning

In the process of cable laying, installation and commissioning of aircraft air conditioning system, TST CABLES follows strict aviation standards and operational procedures. First, according to the layout of the aircraft air conditioning system and the direction of the cable, to develop a reasonable laying program. Then, professional tools and equipment are used to lay and fix the cables to ensure that the cable routing and fixing points meet the design requirements. Finally, carry out debugging and testing of the system to ensure the normal operation and stable performance of the air conditioning system.

9. After-sales maintenance & technical support

TST CABLES provides comprehensive after-sales maintenance and technical support services. Once the aircraft air conditioning system cable has problems or failures, our professional team will respond quickly to provide effective solutions and technical support. At the same time, we also regularly inspect and maintain the aircraft air conditioning system cables to ensure the long-term stable operation of the air conditioning system.

10.Aircraft air conditioning system cable solution case

TST CABLES successfully applied this cable solution in the aircraft upgrade project of a famous Chinese airline. Through the selection of high-temperature flame retardant cables, anti-electromagnetic interference cables and lightweight flexible cables, we have significantly improved the performance and stability of the aircraft air conditioning system. In actual operation, the solution has demonstrated excellent electrical performance and environmental adaptability, ensuring precise control of temperature and humidity in the cabin. At the same time, the safety performance of the cable has been fully verified, and it can work normally in emergency situations, providing important safety protection for passengers and crew.

According to statistics, after applying this cable solution, the failure rate of aircraft air-conditioning system cables has been reduced by 90%, and passenger satisfaction has increased by 70%. The improvement of these data not only proves the effectiveness of this cable solution, but also earns us a high degree of recognition and trust from airlines.

TST CABLES Aircraft Air Conditioning System Cable Solution is characterized by excellent electrical performance, environmental adaptability and safety, and is able to meet the high requirements for cables in the aviation field. Through professional selection, installation and maintenance services, TST CABLES is able to provide customers with reliable and efficient cable solutions to promote the continuous development and progress of aviation.

Other solutions for cables in aviation applications.

WHY CHOOSE TST CABLES

10 years of experience

Specializing in the production of railway cables for 10 years

Engineer-to-engineer one-on-one support

Engineers provide one-on-one service to assist with product selection and problem-solving

Customization according to requirements

With a strong R&D team, we support customized cables based on specific needs

Quality certification

Stringent adherence to industry standards, complete certification

Fully testing facilities

Various tests based on customer requirements

10,000 ㎡ factory

Welcome to visit our factory face to face