You may have heard of the use of titanium alloys and stainless steel in medical devices, but did you know? Even the cables used in surgical robots and MRI equipment are now being quietly replaced with a called PEEK cable called “specialty plastic”. Sounds like a chemical term? Don’t worry, it’s a rising star in the medical world, known as the “king of engineering plastics that can enter the human body.”

Today, TST CABLE Nico will discuss PEEK cable application solutions in the medical industry and explore why it’s driving the craze among top hospitals and device manufacturers worldwide.

- Why is PEEK essential for medical cables?

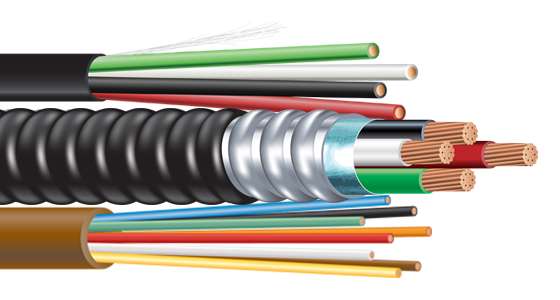

Traditional electrical wiring made of PVC or rubber materials can age, harden, and even release harmful substances over time. However, in medical settings, especially for implantable devices and precision instruments, these “standard” materials simply can’t withstand the harsh conditions.

TST CABLE PEEK (polyetheretherketone) is an ultra-high-performance specialty engineering plastic. Its greatest attributes are: light as plastic, strong as metal, and stable as Mount Tai.

✅ High-temperature resistance: Long-term operating temperature up to 250°C, short-term resistance up to 300°C;

✅ Corrosion resistance: Resistant to alcohol, hydrogen peroxide, gamma radiation, and steam sterilization;

✅ Biocompatibility: ISO 10993 certified, suitable for long-term implantation in the human body;

✅ X-ray transmissive: Does not show up during CT/MRI scans, affecting imaging;

✅ High mechanical strength: Lighter than aluminum, yet more wear-resistant and tensile than steel.

These properties make TST CABLE PEEK an ideal choice for the insulation and jacketing of high-end medical cables.

II. Where is TST CABLE PEEK used? Real-world examples!

- Surgical robots: The “nerves” behind precision

You’ve undoubtedly heard of the da Vinci surgical robot. It can perform millimeter-level precision operations thanks to its densely packed sensor and control circuitry. These cables must be lightweight, bend-resistant, and resistant to electromagnetic interference; any failure would have disastrous consequences.

A domestic head surgery robot company uses TST CABLE PEEK-insulated microcables for signal transmission within the joints of the robotic arm. Results show that after 10,000 consecutive bend tests, the cables remain intact, far exceeding the performance of traditional Teflon materials. An engineer commented, “We used to replace the cables every three months, but now we don’t have to use them for a year.”

- Implantable Medical Devices: Cables that Truly Work “In Vivo”

Pacemakers, deep brain stimulators (DBS), cochlear implants—devices that require long-term implantation in the human body place extremely high demands on their connecting cables.

TST CABLE PEEK is widely used for lead insulation in these devices due to its excellent biostability and fatigue resistance. For example, some of Medtronic’s neurostimulation systems use PEEK-coated electrode leads to ensure they withstand ten years of internal wear, corrosion, and rejection. Even more impressive, PEEK can be modified with barium sulfate to achieve X-ray visibility, facilitating positioning by doctors. It’s a true “smart + safe” combination.

- High-end Imaging Equipment: Say Goodbye to Metal Interference

In an MRI (magnetic resonance imaging) room, any metal can cause image artifacts. Traditional metal-shielded cables are inadequate.

The solution? TST CABLE’s non-magnetic PEEK cable assemblies! Although PEEK itself is non-conductive, it can serve as a structural support or insulation layer when used with optical fiber or silver-plated conductors, ensuring stable signal transmission without compromising image quality.

Some high-end MRI equipment from companies like Siemens and GE Healthcare have begun using PEEK in internal wiring brackets and flexible circuit protection layers, improving overall reliability.

III. Industry Trends: Accelerating Domestic Substitution, the Rise of TST CABLE and TST SEAL

In the past, PEEK material was long monopolized by Victrex in the UK, resulting in high prices and long lead times. However, in recent years, Chinese companies have achieved technological breakthroughs. Companies like TST CABLE and TST SEAL now have the ability to independently produce medical-grade PEEK resin.

At the same time, innovative companies like TST CABLE are applying PEEK to medical screws, connectors, cable fasteners, and other applications, creating “all-PEEK” medical electronics solutions.

According to the “2025 China High-Performance Medical Materials White Paper,” China’s medical PEEK market is expected to achieve a compound annual growth rate of over 18% over the next five years, with the proportion of cable and electronic interconnect applications increasing annually.

IV. Challenges and Prospects

Of course, PEEK is not a panacea. Its processing is difficult and costly, making it unsuitable for all scenarios. However, for medical devices requiring high precision, high reliability, and high safety, PEEK cables are virtually the only option.

With the advancement of 3D printing, miniaturization, and wearable devices, we may see more “invisible PEEK cables” hidden in smart prosthetics, endoscopic robots, and portable dialysis machines, silently protecting lives.

From “Iron Man” to “King of Plastics,” TST CABLE PEEK cables are redefining the possibilities of medical cables. This isn’t just a material upgrade; it’s a crucial step toward safer, smarter, and more user-friendly medical technology.

Next time you step into an operating room or undergo an MRI, consider this: Perhaps, within that delicate device, a tiny PEEK cable is quietly transmitting the signals of life.

Also available in:

English