Extruded corona-resistant polyimide copper flat wire technology innovation: Breakthrough in high-end electromagnetic wire performance

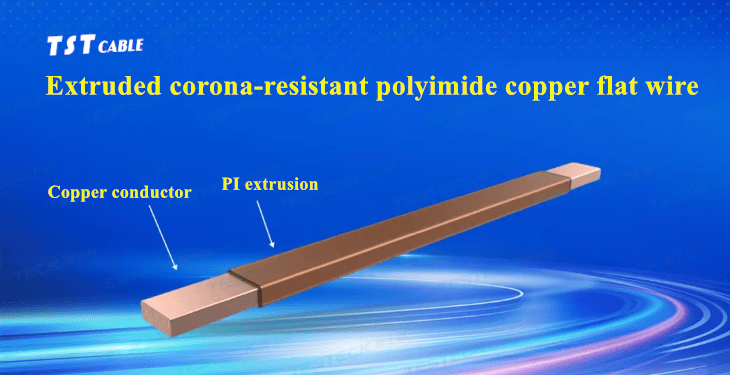

In the fields of new energy vehicles, aerospace, industrial frequency conversion and other high-end equipment, motors and electromagnetic components are facing extreme challenges of high speed, high frequency, wide temperature range and strong electrical stress. The bottlenecks of traditional insulating materials (such as wrapping film and coating paint layer) in reliability, thinness and environmental adaptability are becoming increasingly prominent. As a game-changer in the field of electromagnetic wire, TST cable’s extruded corona-resistant polyimide copper flat wire uses a disruptive continuous extrusion molding process to perfectly composite the polyimide insulation layer with the copper conductor, providing a “0 defect” solution for electromechanical systems under harsh working conditions.

- Improve the insulation process of electromagnetic wire

Traditional polyimide insulated copper flat wires rely on wrapping or coating processes, and have problems such as uneven insulation layer thickness, weak interface bonding, and low production efficiency. The extruded polyimide copper flat wire adopts continuous dense extrusion molding technology to achieve three core breakthroughs:

Material-structure integration: Through micron-level precision design, polyimide particles are directly extruded into a continuous and uniform insulation layer, forming a molecular-level bond with the copper conductor, eliminating the interlayer gap of the traditional process.

Full process controllability: From raw material melting to molding and cooling, the entire process is automated, breaking through the precision limit.

Functional integration innovation: Nano-level corona-resistant fillers are introduced into the polyimide matrix, and after special modification, multiple performance superposition of “insulation + corona resistance + thermal conductivity” is achieved to meet the long-term stable operation under high-frequency pulse environment.

- Four core advantages, combing industry benchmarks

(1) Super strong adhesion: 25% stretching without cracking

Coping with extreme mechanical stress

The traditional wrapped insulation layer is prone to delamination and cracking when the conductor is bent or stretched, resulting in partial discharge or even short circuit.

TST cable measurement site

(2) Extremely light and thin: 0.08mm ultra-thin film thickness

Free up space and efficiency

With the precise control of the extrusion process, the thickness of the insulation layer can be as thin as 0.08mm or even thinner (the minimum thickness of the traditional wrapping process is 0.20mm). Under the same conductor cross-sectional area, the overall outer diameter of the electromagnetic wire is reduced by 30%-40%.

TST cable test site

(3) Good density: PDIV and BDV values are greatly improved

The density of the insulation layer directly determines the corona resistance performance. The extruded polyimide greatly improves the PDIV and BDV values through a pinhole-free continuous structure, making it the only choice for high-frequency scenarios such as industrial inverters and aerospace motors.

(4) Wide temperature range: -269℃~400℃

Broaden the extreme temperature range

This product can operate for a long time at -269℃ to 260℃ and withstand a high temperature of 400℃ for a short time. Whether it is the high temperature area of the motor of the aircraft engine accessories or the superconducting winding of the low-temperature refrigeration equipment, the insulation performance can be kept stable, completely breaking the traditional dilemma of “low temperature embrittlement and high temperature softening”.

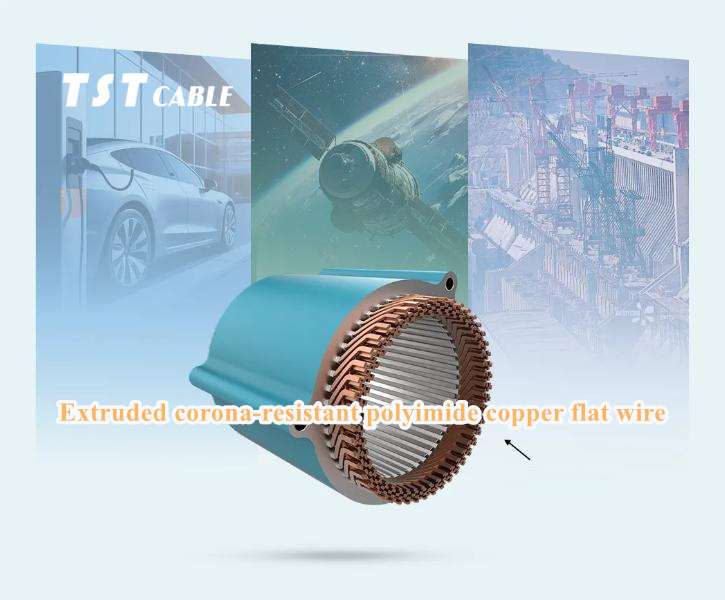

- Full-scenario adaptation: the right choice for high-end equipment

(1). New energy vehicles: low dielectric loss and corona resistance

In 800V high-voltage drive motors, the peak pulse voltage of the winding exceeds 1500V. Traditional insulation materials are prone to partial discharge and premature failure. Extruded polyimide copper flat wire improves motor efficiency with its high PDIV, low dielectric loss and corona resistance.

(2). Aerospace: Lightweight and high reliability

In aviation motors and aerospace solenoid valves, the product’s ultra-thin size (15% weight reduction) + wide temperature adaptability (-269℃~260℃) + radiation resistance are irreplaceable.

(3). Industry and Energy: Challenging Extreme Working Conditions

Photovoltaic/wind power inverters: Under high-frequency IGBT drive, corona resistance ensures long-term trouble-free operation and reduces operation and maintenance costs;

High-speed traction motors: Mechanical vibration and high temperature resistance meet the stringent requirements of high-speed rail and rail transit motors;

Special transformers: Ultra-thin insulation achieves high power density, suitable for extreme environments such as shipboard and plateau.

As the high-end equipment manufacturing industry evolves towards “higher power density, wider temperature range, and stronger electrical stress tolerance”, electromagnetic wires, as core basic components, are moving from “passive adaptation” to “active empowerment”. The birth of extruded corona-resistant polyimide copper flat wire is not only a breakthrough in a product, but also an innovation in material technology and design concepts.

If you want to learn about TST cable’s innovative product “Extruded corona-resistant polyimide (PI) cable”, please send an email to TST cable’s official cable engineer to obtain new product information and quotes!

Also available in:

English