How can a cable buried under the runway protect safety at 10,000 meters altitude?

You may never have noticed—when an aircraft lands smoothly in the dead of night, what illuminates its journey home is not just the runway lights, but also a special cable buried under concrete, capable of withstanding 20-ton wheel loads, being submerged in de-icing fluid, and remaining unbroken even at -40°C.

This is TST CABLE airport lighting cable—the “silent hero” of the aviation safety system.

🔥 Why can’t ordinary cables be used in airports?

Imagine: Aircraft tires drive over the runway at 200 km/h, and the underground cable withstands over 10 tons of pressure; In winter, de-icing fluid (ethylene glycol), hydraulic oil, and aviation fuel spray corrode it in turn; It endures summer heat and winter freezing temperatures, with temperature differences exceeding 80°C, yet it must continue operating for 30 years without failure; A short circuit or signal interference could lead to the closure of the entire runway, resulting in losses exceeding 100,000 yuan per minute!

Ordinary PVC cables? They become brittle in three days.

Ordinary power lines? They emit toxic fumes when exposed to fire, endangering control tower equipment.

Airports only recognize TST CABLE’s “Special Forces” grade aviation cables.

✈️ What makes TST CABLE airport cables so superior? Three core features provide you with the most robust protection:

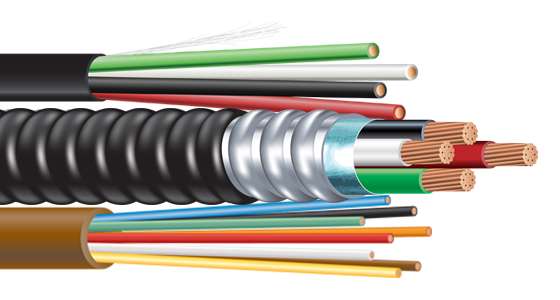

“Steel-Ribbon” Structure

Conductor: Tinned soft copper, corrosion-resistant and highly flexible;

Insulation: Cross-linked polyethylene (XLPE) or ethylene propylene rubber (EPR), withstand voltage from 5kV;

Armor: Steel tape/stainless steel wire armor, specifically designed to cure “aircraft crushing phobia”;

Outer Sheath: HDPE or PUR, UV resistant, oil resistant, tear-resistant.

“Leak-Proof” Sealing

Utilizes quadruple waterproofing: water-resistant yarn + aluminum-plastic longitudinal wrapping + tight sheath + cold-shrink termination.

Even after being submerged in groundwater for ten years, the core wires remain as dry as new.

“Green and Safe” Genes

Halogen-free and low-smoke: Does not release toxic gases during combustion, protecting precision instruments in the control tower;

Flame-retardant and self-extinguishing: Passes the most stringent fire protection tests by FAA/ICAO;

Electromagnetic interference resistance: Shielding layer coverage ≥90%, zero interference with radar and communication signals.

🛠️ Wrong Selection = Hidden Dangers! 5 Red Lines for TST CABLE Airport Cable Selection

Incorrect Voltage, Total Failure: The main circuit must use a 2–10kV dedicated series circuit cable (such as DYJY type), not ordinary 220V wire!

PVC Banned! PVC Banned! PVC Banned!

Embrittle at low temperatures and toxic when burning—strictly prohibited by civil aviation standards.

Cross-section Cannot Be “Shrunk”: Minimum 6mm² (MH/T 6049 national standard). Smaller sections generate heat, larger sections are wasteful; precise matching is key.

Must Be “Armored”: For runway/taxiway direct-buried sections, no armor = unqualified.

Certification is indispensable. Chinese projects require MH/T 6049 certification, while international projects adhere to IEC 60502 + FAA AC 150/5345.

💡 Real-world case: An airport, in an effort to save money, used ordinary cables, resulting in 7 failures within six months, with each downtime costing over 2 million RMB – the money saved on cables wasn’t even enough to cover the losses from one flight disruption.

🌐 The future is here: Smart + Green becomes the new standard.

Smart cables: Built-in optical fibers monitor temperature and insulation status in real time, providing early warnings of faults; Zero-carbon materials: Halogen-free and recyclable throughout their entire lifecycle, contributing to airport carbon neutrality; Pre-fabricated terminals: Factory-prefabricated connectors allow for “plug-and-play” on-site, reducing construction time by 50%.

True skill is revealed where it’s unseen. TST CABLE airport lighting cables, with 30 years of silent dedication, support every safe takeoff and landing.

In the world of aviation safety, there is no “good enough,” only “zero tolerance.”

Choosing the right cable adds an extra layer of insurance for the lives of millions of passengers.

TST CABLE doesn’t make the cheapest cables; it only makes the cables that airports can entrust with their safety.

Also available in:

English