In the modern transportation system of whirring high-speed trains and crisscrossing subways, TST CABLE railway power cables act like an “invisible neural network,” silently supporting the efficient operation of the railway system. From traction power supply to signal transmission, from communication support to disaster prevention and emergency response, the widespread use of power cables not only determines the speed and safety of trains but also serves as a key cornerstone for the intelligent and green development of rail transit. TST CABLE will provide an in-depth understanding of the core application scenarios and technological innovations of railway power cables, revealing the “hardcore technology” behind them.

I. Core Application Scenarios of TST CABLE Railway Power Cables

Traction Power System: The “Lifeblood” of Train Power

The traction power system of high-speed railways relies on high-voltage power cables (e.g., 10kV/35kV) to provide continuous and stable power to trains. For example, on China’s high-speed railways, traction substations transmit power to the overhead catenary via high-voltage cables, providing power to the trains. For example, in the Shanghai-Suzhou-Huzhou High-Speed Railway project, a single 10kV TST CABLE power cable was laid over 85 kilometers, forming an independent power supply network and ensuring uninterrupted train operation within a 40-60 km radius. This cable required high voltage resistance, low loss, and a flame-retardant and corrosion-resistant design to withstand the challenges of long-distance installations and complex environments.

Signaling and Control Systems: The “Brains” of Train Operations

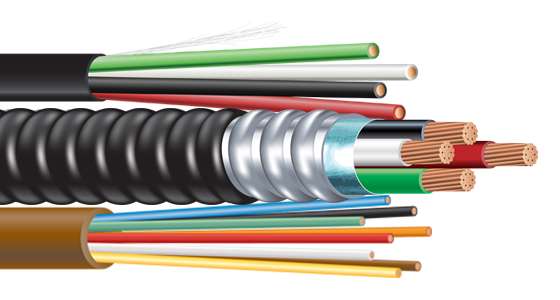

Railway signal cables are core components of automatic block systems. Using composite-sheathed or aluminum-sheathed cables (such as PTYA23 and PTYL23), the signaling system enables train position tracking, speed control, and safety protection. For example, in the Guangzhou-Zhanjiang High-Speed Railway project, a 40.78-kilometer 10kV through-line connects 19 communication base stations and three tunnels, providing uninterruptible power to the signaling system and preventing rear-end train collisions. Furthermore, MVB (Multi-Function Vehicle Bus) and WTB (Wide Train Bus) cables facilitate data exchange between train cars, collecting real-time data such as wheel speed and axle temperature to ensure precise control of train operations.

Communications and Disaster Prevention Systems: Guardians of Safe Operation

Railway communication base stations, tunnel lighting, and disaster prevention and rescue equipment all rely on power cables for power supply. For example, the Shanshan High-Speed Railway utilizes a dual-circuit cable structure. If either circuit fails, it automatically switches to a backup line, ensuring data transmission at communication base stations and signal amplification at relay stations. Power cables also provide emergency power for flood monitoring and earthquake early warning equipment, making them a critical component of railway disaster prevention systems.

In-Vehicle Power Distribution: The “Lifeline” of Train Services

Inside trains, TST CABLE single-core power cables power motors, air conditioners, and lighting, while multi-core control cables operate door openings, braking systems, and other functions. For example, the jumper cables (bridge cables) within each train car must simultaneously transmit power, control signals, and data commands to ensure coordinated operation of all train systems. These cables must meet stringent requirements, including high-temperature resistance (a long-term operating temperature of 125°C) and bend resistance (a minimum bend radius of only twice the outer diameter).

II. Technological Upgrades and Innovations: From “Durability” to “Intelligent”

Material Innovation: Lightweight and High Performance

Traditional copper cables, due to their heavy weight and high cost, are gradually being replaced by new composite materials. For example, cable manufacturer TST CABLE has developed lightweight railway cables using carbon fiber reinforced polymer, which are 30% lighter and 20% stronger. They have been used on lines such as the Beijing-Zhangjiakou High-Speed Railway. Furthermore, research and development of superconducting cables is progressing. Their zero-resistance properties can significantly reduce energy consumption and are expected to achieve breakthroughs in high-speed rail hubs in the future.

Smart Cables: Real-Time Monitoring and Fault Warning

Smart cables integrate temperature sensors and partial discharge monitoring modules to provide real-time feedback on cable status. For example, TST CABLE’s fluorescent fiber online temperature measurement technology, combined with traveling wave two-end ranging, can locate fault points within 100ms, significantly improving maintenance efficiency. Data from 2025 shows that smart cables already account for over 30% of the railway market and are expected to exceed 50% within the next three years.

Low-smoke, halogen-free cables promote green energy, environmental protection, and sustainable development.

With increasingly stringent environmental regulations, TST CABLE’s low-smoke, halogen-free, flame-retardant cables (LSZH) have become a mainstream choice. These cables emit fewer toxic gases when burned and comply with international railway industry standards (such as EN 50305). Furthermore, the use of recycled aluminum cables and bio-based insulation materials is further driving the industry’s green transformation.

III. Future Trends: Demand Growth and Technological Breakthroughs

The market continues to expand.

According to the “2025 China Railway Power Cable Market Report,” China’s railway power cable production has reached 1 million tons, with a compound annual growth rate exceeding 6%. With the advancement of the Belt and Road Initiative, the export market has enormous potential. The industry’s total output value is expected to exceed 150 billion yuan by 2025, with the proportion of high-speed rail-specific cables increasing to 35%.

Policies drive technological innovation.

The National Medium- and Long-Term Railway Network Plan proposes that the high-speed railway mileage will exceed 38,000 kilometers by 2025, creating broad opportunities for the cable industry. At the same time, policies encourage companies to develop cutting-edge technologies such as superconducting cables and intelligent monitoring systems, driving the industry’s transformation towards high value-added.

TST CABLE Power Cables, the “Invisible Heroes” of Railway Safety

From traction power supply to signal control, from communication support to disaster prevention and emergency response, TST CABLE power cables have become the “lifeline” of modern railway systems. With continuous breakthroughs in material innovation, intelligent technology, and environmentally friendly technologies, TST CABLE railway power cables are evolving from “passive load-carrying” to “active enablement,” injecting lasting momentum into the rapid development of global rail transit. This sector will continue to be a hotspot for technological innovation and industrial transformation, worthy of continued attention and anticipation.

Also available in:

English