Advantages of Extruded Cables

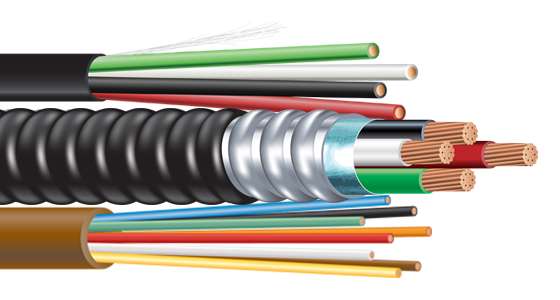

Extruded cables are cables manufactured by continuously extruding polymer materials such as insulation and sheaths uniformly coating the conductor or core surface. As a mainstream technology in modern cable manufacturing, extrusion is widely used in power, communication, control, and special cables. Its core advantages are reflected in multiple dimensions, including performance consistency, production efficiency, material adaptability, and cost control.

I. Excellent Electrical and Physical Performance Consistency

* Uniform Coating: The extruder, through precision molds (such as catenary CCV or vertical VCV), achieves insulation/sheath thickness tolerances of ≤±5%, significantly superior to traditional processes such as wrapping and impregnation.

* No Air Gap Defects: The molten material tightly adheres to the conductor, avoiding partial discharge caused by air gaps, improving the breakdown strength and lifespan of high-voltage cables.

* Strong Interface Bonding: In the high-temperature molten state, the material forms good adhesion with the conductor/shielding layer, reducing the risk of delamination.

✅ Typical Application: Cross-linked polyethylene (XLPE) power cables of 110kV and above must employ a three-layer co-extrusion process to meet IEC 60502 requirements for eccentricity and partial discharge.

II. TST Cable’s High Efficiency and Large-Scale Production Capabilities

Continuous Production: A single production line can achieve full automation from “coiling—conductor preheating—three-layer co-extrusion—cross-linking—cooling—winding,” at speeds of 30–100 meters/minute;

Low Labor Dependence: Compared to manual wrapping or braiding, extrusion processes reduce labor costs by over 60%;

Suitable for Large-Volume Orders: Applicable to fields with high demand for standard cables, such as construction, aviation, nuclear power, shipbuilding, power grids, and rail transportation.

III. Broad Material Compatibility and Functional Expansion

Extrusion processes are adaptable to a variety of polymer materials, meeting diverse performance requirements:

Material Type | Properties | Application Scenarios

PVC | Low cost, flame retardant | Ordinary building wires, control cables

XLPE | Heat resistant to 90℃, excellent electrical performance | Medium and high voltage power cables

LSOH | Low smoke, halogen-free, environmentally friendly | Subways, hospitals, data centers

Silicone Rubber | Soft, temperature resistant -60~200℃ | High-temperature mobile devices, robots

Fluoroplastics | Chemical corrosion resistant, good high-frequency performance | Aerospace, semiconductor equipment

Furthermore, special functions can be imparted to cables through blending modification (such as adding flame retardants, UV inhibitors, conductive carbon black).

IV. Flexible Structural Design, Supporting Complex Constructions

Multi-layer Co-extrusion: Simultaneous extrusion of inner shielding + insulation + outer shielding (three-layer co-extrusion) improves the uniformity of the electric field in high-voltage cables;

Irregular Cross-sections: Flat cables, elliptical cables, and ribbon cables can be produced through customized molds, saving space (e.g., elevator traveling cables);

Online Composite: Optical fibers, tear cords, identification color strips, etc., can be embedded during extrusion to achieve multi-functional integration.

V. Cost and Environmental Advantages

High Material Utilization: Waste materials can be recycled and granulated, with a loss rate of <3%;

Energy Optimization: Modern extruders employ high-efficiency heating and closed-loop temperature control, reducing energy consumption per unit capacity by 20%;

Compliant with Green Manufacturing Trends: Supports halogen-free and recyclable material extrusion, helping companies achieve ESG goals.

Why have TST CABLE extruded cables become the industry mainstream?

“Consistent, efficient, flexible, and reliable”—TST CABLE’s extrusion process elevates cables from “usable” to “precise and reliable.”

Whether it’s XLPE insulated cables for urban power grids, cross-linked polyolefin sheathed cables for deep-sea wind power, or high-voltage silicone wires for new energy vehicles, extrusion technology is indispensable.

TST CABLE is equipped with a three-layer co-extrusion production line and an online eccentricity meter + spark detection system, ensuring that every meter of extruded cable achieves millimeter-level precision and microvolt-level insulation reliability—because they deeply understand that in the world of power transmission, stability begins with a perfect extrusion.

Also available in:

English