Do you know the selection criteria for military-standard airport lighting cables?

I. Core Selection Criteria for TST CABLE Mil spec wire aerospace wire

1. System Type and Voltage Level

Series Main Circuit System (Mainstream):

Powered by constant current dimmers, voltage is typically 2–5 kV or 10 kV;

Must use dedicated airport navigation lighting buried cables (such as DYJY type), complying with MH/T 6049-2020 (Chinese Civil Aviation Standard) or IEC 60502.

Parallel Circuit System (Minority Auxiliary Lighting):

Voltage is generally 230/400 V, and flame-retardant and weather-resistant power cables (such as WDZ-YJY) can be used.

2. Installation Method and Mechanical Protection

Installation Area Requirements

Direct burial in runway/taxiway Burial depth ≥1.2 m, cable requires steel tape armor (SWA) or stainless steel wire armor, compressive strength ≥10 kN

Embedded in light pits Cable requires high flexibility, bending radius ≤12D, sheath is wear-resistant and oil-resistant

Crossing roads/pipe corridors Add galvanized steel pipes or HDPE protective pipes, pipe diameter ≥2×cable outer diameter

3. Conductor and Cross-section

Material: Priority is given to tinned soft copper conductors (to improve corrosion resistance, complying with GB/T 3956 Class 5);

Cross-section: The main circuit is usually 1×6 mm², 1×10 mm² (MH/T 6049 specifies a minimum of 6 mm²);

Structure: Compact stranded, reducing eddy current loss and improving current carrying capacity. 4. Insulation and Sheath Materials

Material Type | TST CABLE Military Standard Airport Lighting Cable Performance Advantages | Applicable Scenarios

XLPE | Heat resistant (90℃), high dielectric strength, resistant to water treeing | Airport main buried cables

EPR | Flexible, low temperature resistant (-55℃), crack resistant | Cold regions or mobile connection sections

HDPE Sheath | Abrasion resistant, UV resistant, chemical corrosion resistant | Outdoor direct burial

PUR Sheath | High elasticity, oil resistant, tear resistant | Luminaire connection wires, areas with frequent bending

✅ PVC is prohibited: Due to low-temperature embrittlement and the release of toxic halogen gases during combustion, it does not comply with airport safety regulations.

5. Safety and Environmental Performance

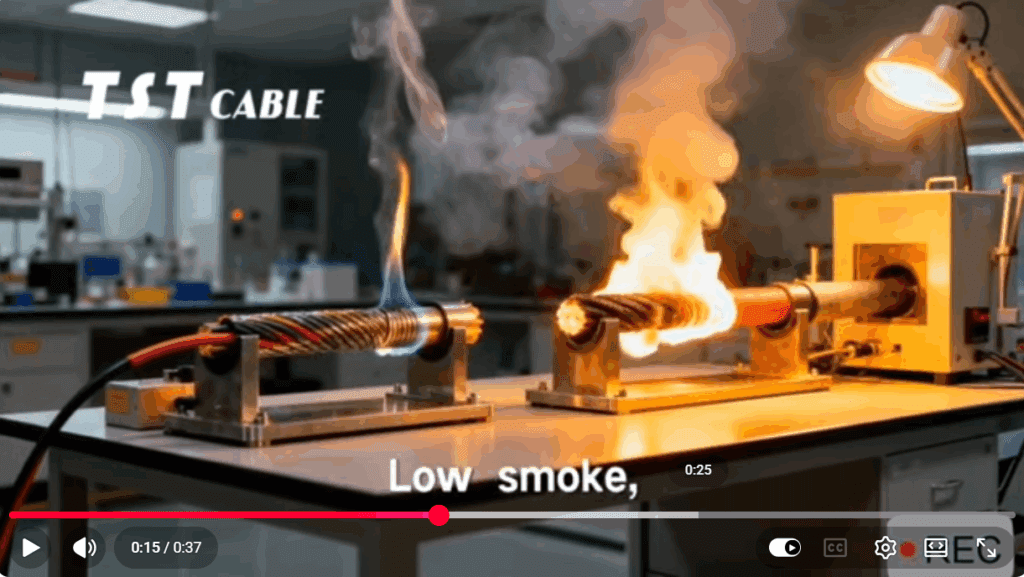

Flame Retardant: Passes IEC 60332-3 bundled cable combustion test (at least Class C);

Low Smoke Zero Halogen (LSOH): Complies with IEC 60754-2, smoke density ≤50%, pH ≥4.3;

Halogen-free: Avoids corrosion of precision navigation equipment;

Rodent and Insect Repellent: A layer to prevent biological damage is required for tropical/subtropical airports.

6. Sealing and Waterproofing

Longitudinal Water Blocking: Uses water-swellable tape or aluminum-plastic composite wrapping;

Radial Waterproofing: Sheath is pinhole-free, passes 0.2 MPa/24h immersion test;

Connector Compatibility: Supports cold-shrink/heat-shrink terminals, ensuring IP68 protection. II. Mandatory Certification and Standards

Region | Standard/Certification | Key Requirements

China | MH/T 6049-2020 | Mandatory civil aviation industry standard, specifying structure and test methods

International | IEC 60502-2, ICAO Annex 14 | Electrical performance, installation safety

Europe/America | FAA AC 150/5345-53D, UL 1581 | Material weather resistance, flammability rating

European Union | EN 50575 (CPR) | Fire performance classification (e.g., B2ca-s1,d1,a1)

III. Selection Process Recommendations

Clarify system parameters: Voltage, current, circuit length, dimming level;

Inspect installation environment: Temperature range, chemical exposure, mechanical stress, groundwater level;

Match standard requirements: Prioritize products certified to MH/T 6049 or IEC standards;

Verify supplier qualifications: Possess experience in civil aviation projects, provide type test reports;

Consider total life cycle cost: Prioritize products with a lifespan of ≥30 years and maintenance-free design.

The selection of aerospace wire is not simply about “usability,” but about “absolute reliability.”

Every meter of cable represents a commitment to zero accidents, zero interruptions, and zero compromises on safety.

Choosing TST CABLE’s aviation-grade standard cables, which meet military-grade quality standards, is the first line of defense in ensuring safe flight operations.

Also available in:

English