Submersible oil pump cables (ESP cables) in oilfield development often face challenging well conditions such as high temperature, high pressure, high corrosion (“three highs”), sand content, high inclination/horizontal wells, and high gas content. To ensure the long-term stable operation of the electric submersible pump system, the cable structure, materials, and installation methods must be specifically optimized. The following are the key strategies of TST CABLE’s submersible oil pump cables to address various special well conditions:

I. High-Temperature Wells (>150℃)

Challenge: Ordinary ethylene propylene rubber (EPR) insulation ages and cracks rapidly above 180℃.

Solution:

Insulation upgrade: Use fluororubber (FPM) or cross-linked polyolefin resistant to temperatures of 200–230℃;

Sheath matching: Use hydrogenated nitrile butadiene rubber (HNBR) or fluororubber (FKM) to prevent thermal deformation;

Conductor optimization: Tinned copper wire enhances high-temperature oxidation resistance.

✅ Application case: A well in the Tarim Oilfield had a bottom-hole temperature of 210℃. Using an FKM sheath + FPM insulated cable, it operated continuously for 42 months without failure.

II. Highly Corrosive Wells (containing H₂S, CO₂, and high salinity water)

Challenge: H₂S causes “sulfide embrittlement” and fracture of the metal shielding layer, and acidic fluids corrode the sheath.

Solution:

Metal-free structure: Eliminate copper tape shielding and use a fully rubber-coated three-core flat cable to eliminate electrochemical corrosion points;

Sulfur-resistant materials: The sheath uses HNBR or FKM certified by NACE MR0175/ISO 15156;

Reinforced sealing: The ends use double-layer heat shrink tubing + epoxy potting to prevent corrosive media from penetrating along the cable core.

III. Deviated and Horizontal Wells (well inclination >60°)

Challenge: The cable is subjected to tension and compression in the curved section, which can easily lead to wear, deformation, and even short circuits. Solutions:

Prioritize the use of flat cables: Thin and flexible, they conform to the inner wall of the casing, reducing friction;

Enhanced tensile strength structure: Built-in aramid fibers or stainless steel wire reinforcement cores to share mechanical stress;

Optimized laying process: Use a dedicated centralizer to control the lowering speed and avoid “snake-like buckling”.

IV. High Sand Content/Sand Production Wells

Challenge: Formation sand erodes the cable surface with the fluid flow, leading to sheath wear.

Solutions:

High wear-resistant sheath: HNBR hardness ≥80 Shore A, wear resistance is 3 times higher than neoprene;

Thickened design: Sheath thickness increased by 20–30%, extending wear life;

Local protection: Install a stainless steel spiral sheath near the pump suction inlet to resist direct impact from sand particles.

V. High Gas-Oil Ratio (GOR) or Gas Locking Risk Wells

Challenge: Free gas accumulates around the cable, affecting heat dissipation and causing localized overheating.

Solutions:

Optimized cable layout: Ensure the cable is tightly against the inner wall of the casing to reduce gas retention space;

Select high thermal conductivity sheath materials: Such as HNBR with ceramic fillers to improve heat dissipation efficiency;

Use downhole separators: Reduce the amount of gas entering the pump area from the source, indirectly protecting the cable.

VI. Deep Wells (>3,000 meters) and Ultra-Deep Wells

Challenge: High hydrostatic pressure (>30 MPa), cable deformation under pressure, and reduced insulation performance.

Solutions:

High pressure resistance structure: Adopt a tightly twisted + high filling coefficient design to reduce voids;

Pressure balancing technology: Some high-end cables have built-in pressure compensation oil chambers, making the internal and external pressure difference close to zero;

Voltage level matching: Select 10 kV cables to reduce current and heat generation. TST CABLE Customized Cable Capabilities Support:

Comprehensive Material Library: Four major systems available: EPR / HNBR / FKM / FPM;

Flexible Structure: Customizable combinations including round cables, flat cables, reinforced cables, and unshielded cables;

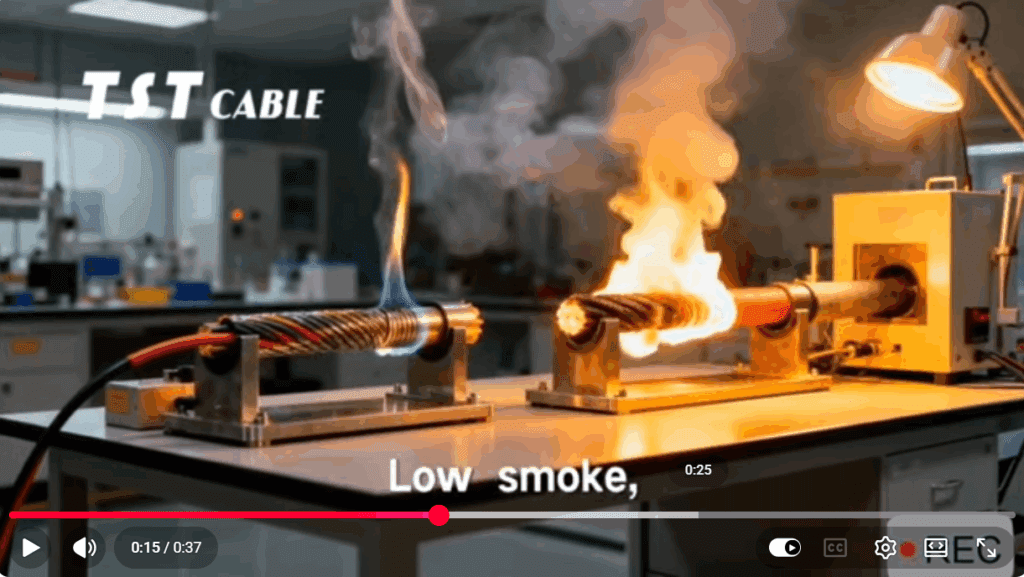

Rapid Verification: Provides well condition simulation testing (high-temperature, high-pressure corrosion chamber + bending fatigue test);

On-site Service: Engineers can participate in cable selection, laying supervision, and fault analysis.

In the face of complex oilfield environments, there is no “one-size-fits-all cable,” only “precise adaptation.”

TST CABLE uses material science as its spear and engineering experience as its shield to tailor submersible pump cable solutions for each unique well.

Because we understand that under thousands of meters of strata, every extra day of operation means an extra ton of oil produced; and every avoided pump failure saves hundreds of thousands of yuan.

Also available in:

English