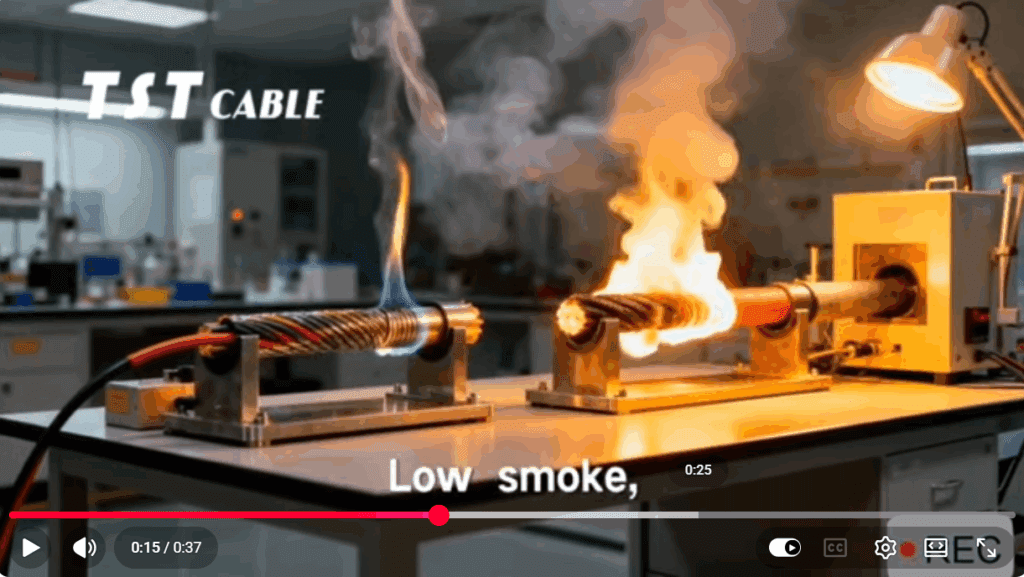

The safety performance of low-smoke halogen-free cables is crucial. Their quality isn’t just a claim; it’s regulated and verified by a series of rigorous national standards and testing methods. The following are the key specific testing standards for TST CABLE low-smoke halogen-free cables, covering core safety indicators such as flame retardancy, low smoke, halogen-free, toxicity, and corrosiveness.

I. Core National Standards

GB 31247-2014 “General Rules for Flame-Retardant and Fire-Resistant Wires, Cables, or Optical Fiber Cables”

Status: This is currently the most core and authoritative standard for flame-retardant cables in China, replacing the flame retardancy classification section of the older GB/T 19666-2005.

Key Content:

Flame retardancy is categorized into B1 (flame retardant), B2 (flame retardant), and B3 (ordinary). B1 is the highest level and is commonly used in high-security locations such as subways, airports, and hospitals. In addition to flame retardancy, this evaluation also comprehensively assesses smoke toxicity, corrosiveness, and combustion drippings during combustion, achieving a comprehensive performance assessment.

For “low-smoke, halogen-free, flame-retardant B1-grade cables,” the following conditions must be met simultaneously:

Flame retardancy: B1-grade;

Smoke generation characteristics: Smoke density during combustion must meet s1-grade (high light transmittance);

Droplets/particles: d0-grade (no persistently burning drippings);

Smoke toxicity: t0-grade (extremely low smoke toxicity, no impact on escape);

Corrosiveness: A1-grade (extremely low halogen acid gas content, pH ≥ 4.3, conductivity ≤ 10 μS/mm).

GB/T 19666-2019 “General Rules for Flame-Retardant and Fire-Resistant Wires and Cables”

Status: As a general standard, it specifies the designation and technical requirements for flame-retardant cables and serves as the basis for product model designations. Key Content:

Defines series codes such as WDZ (halogen-free, low-smoke, flame-retardant) and WDZA/B/C (Class A/B/C flame-retardant).

Although GB 31247-2014 has become a higher-level performance standard, GB/T 19666-2019 is still widely used to guide production and market labeling.

II. Specific Test Method Standards for Key Performance

These standards detail how to test various cable properties:

Halogen-free Performance Test (to test for the release of harmful halogen acid gases)

Standard: GB/T 17650.2-1998 / IEC 60754-2

Test Content: The cable material is burned at high temperature and the generated gases are collected.

Measure the pH of the aqueous solution: Requirement: ≥ 4.3 (the lower the pH, the stronger the acidity and the greater the corrosiveness).

Measure the conductivity of the aqueous solution: Requirement: ≤ 10 μS/mm (the lower the conductivity, the lower the ion concentration and the less corrosiveness). Significance: Ensures that large amounts of toxic and corrosive gases such as hydrogen chloride (HCl) are not produced during a fire.

Low Smoke Performance Test (Tests smoke density)

Standard: GB/T 17651.2-1998 / IEC 61034-2

Test Content: Burn a cable sample of a specified length in a closed, transparent chamber. A light source and a photosensitive receiver are used to measure the degree to which the smoke blocks light during combustion.

Evaluation Indicator: Minimum light transmittance. Requirement: ≥ 60%.

Significance: A higher light transmittance indicates thinner smoke and better visibility, which helps personnel identify escape routes during a fire.

Flame Retardancy Test (Tests flame spread)

Bundled Burning Test:

Standard: GB/T 18380.3 / IEC 60332-3

Test Content: Arrange multiple cables in a vertical bundle and burn them with a flame of a specified calorific value for a specified period of time. After the flame is removed, the extent of charring is observed.

Classification: Classified by the number of specimens and the height of charring, they are classified into Class A, Class B, and Class C (Class A has the most stringent requirements). Note: This is a different grading system than the B1/B2/B3 in GB 31247.

Single Vertical Flame Test:

Standard: GB/T 18380.1 / IEC 60332-1

Test Content: Flame is applied to a single cable. After removing the fire source, check for self-extinguishing.

Result: Pass or Fail.

Smoke Toxicity Test (Tests for Biological Hazards of Smoke)

Standard: Method referenced in GB 31247-2014

Test Content: This is a higher-level test, typically using animal exposure studies or chemical analysis, to assess the effects of combustion smoke on the respiratory system of organisms over a specified time period.

Requirement: For Class B1 cables, a t0 rating must be achieved, meaning the smoke toxicity is extremely low and will not cause fatal or serious injury within the specified exposure time.

What should a qualified low-smoke, halogen-free cable test report contain? A complete test report (usually issued by a nationally recognized third-party laboratory, such as the Shanghai Cable Research Institute, the National Fireproof Building Materials Quality Supervision and Inspection Center, or TST CABLE Laboratory) will test the cable sample according to the above standards and clearly list the results:

Flame retardancy rating: Whether it meets the B1/B2 requirements of GB 31247-2014.

Low smoke performance: Whether the light transmittance is ≥ 60% (according to GB/T 17651.2).

Halogen-free performance: Whether the pH value is ≥ 4.3 and the conductivity is ≤ 10 μS/mm (according to GB/T 17650.2).

Additional performance: Whether the d0, t0, and a1 grades are met (according to GB 31247-2014).

When purchasing, consumers and contractors should always request a recent test report issued by a reputable organization covering the above key items, rather than simply relying on product promotional materials. This is fundamental to ensuring project fire safety.

Also available in:

English