You might think the biggest fears for space shuttles, satellites, and space stations are explosions or loss of contact? Actually, there’s another “invisible killer”—the dense smoke and toxic gases produced by burning cables. In a confined spacecraft, even a short circuit and fire in a single wire, releasing corrosive gases like hydrogen chloride, could instantly paralyze equipment worth billions and even endanger the lives of astronauts.

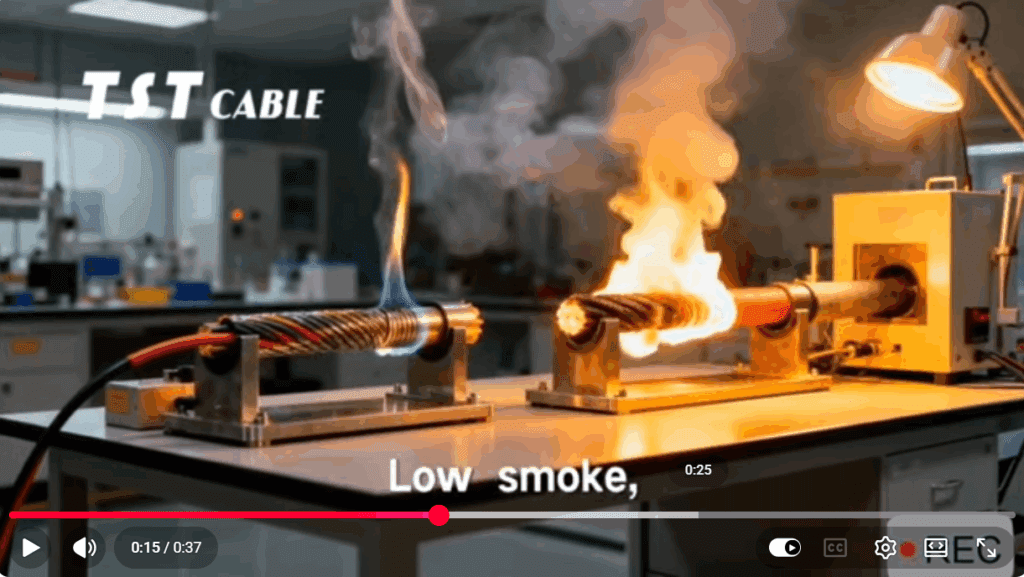

This is why top aerospace projects worldwide have already undergone comprehensive upgrades—TST CABLE low-smoke halogen-free flame-retardant cables (LSZH cable) have become standard equipment. Not only are they “non-toxic when burned,” but they are also ultra-light, ultra-strong, and ultra-stable, truly the “nerve armor” of space missions. Low-smoke halogen-free cables are as light as a feather, as stable as a rock, and don’t emit toxins when burned!

I. Why is low-smoke halogen-free cable indispensable in aerospace?

Imagine this: On the International Space Station, the air circulation system operates 24/7. If a traditional PVC cable catches fire, toxic fumes cannot escape, and astronauts would be poisoned within minutes. Worse still, acidic gases could corrode precision sensors and navigation chips, causing the entire system to collapse.

TST CABLE’s low-smoke halogen-free cables, using cross-linked polyolefins or special fluoropolymers as insulation, produce the following when burning:

✅ Almost no toxic gases (halogen content close to zero);

✅ Minimal smoke, with a light transmittance >60%, ensuring visibility in emergencies;

✅ No corrosion to equipment, protecting expensive avionics systems.

More importantly—it’s incredibly lightweight! In the aerospace industry, “every gram is gold.” TST CABLE’s low-smoke halogen-free material is 15%~20% lighter than traditional PVC. Saving tens of kilograms of cable weight on a rocket allows for more fuel or scientific instruments to be carried.

II. Application Cases: From Shenzhou Spacecraft to Artificial Satellites, They Are Used Everywhere

- China’s Space Station & Shenzhou Spacecraft: Domestically Produced LSZH Cables Take to Space

According to the China Aerospace News, the internal wiring systems of the Tianhe core module and the Shenzhou manned spacecraft have fully adopted low-smoke halogen-free flame-retardant cables that meet GJB standards. Especially in critical circuits such as life support, communication, and attitude control, special LSZH cables resistant to radiation and extreme temperatures (-65℃~+150℃) are used to ensure absolute safety in the extreme space environment. - Artificial Satellites: Lightweight + High Reliability

The internal wiring of artificial satellites is extremely dense. To reduce weight and improve safety, a large number of low-smoke halogen-free micro-cables are used inside satellites for flight control and sensor networks. These cables have not only passed rigorous certification but can also withstand the severe vibrations during launch and the high-temperature impacts during atmospheric reentry. - C919 Passenger Aircraft: A Benchmark for Commercial Aviation

The C919 passenger aircraft extensively uses low-smoke halogen-free shielded cables in its electrical system. The total length of the cabling exceeds 100 kilometers, all meeting the stringent requirements of the FAA and EASA regarding smoke toxicity, flame retardancy, and electromagnetic compatibility. Even in the event of a fire, passengers have sufficient time to evacuate, and critical systems will not be destroyed by toxic gases.

III. How High is the Technical Threshold? Not Just Anyone Can Make It

TST CABLE’s aerospace-grade low-smoke halogen-free cables are not something ordinary factories can produce. They must simultaneously meet the following requirements:

Extreme temperature adaptability: from -100°C in low Earth orbit to +200°C in atmospheric reentry;

Resistance to cosmic rays and atomic oxygen corrosion;

Ultra-high purity materials: preventing the release of volatile substances that could contaminate optical lenses or experimental modules;

Ultra-fine diameter + high flexibility: adaptable to wiring in confined spaces;

Compliant with international aerospace standards such as NASA ASTM E662 and ESA ECSS-Q-ST-70-08C.

Currently, only a handful of manufacturers worldwide can reliably supply these cables: in Europe and America, there are Carlisle, TE, and Nexans Aerospace; in China, TSTCABLE and TST SEAL have achieved technological breakthroughs.

IV. Industry Trends: Accelerated Domestic Substitution, Smart Cables Take to the Skies

In the past, China’s aerospace industry relied heavily on imported high-end cables. However, in recent years, with breakthroughs in TST CABLE’s high-performance polyolefin resin, nano-flame retardants, and irradiation cross-linking technology, domestically produced low-smoke halogen-free cables have been successfully applied to projects such as the Chang’e lunar exploration program, BeiDou navigation, and commercial rockets.

In the future, TST CABLE’s even “smarter” cables are on the way:

Fiber optic composite cables: faster data transmission and stronger anti-interference capabilities;

Self-monitoring cables: built-in fiber optic sensors provide real-time feedback on temperature and strain status;

Degradable and environmentally friendly materials: used in near-Earth orbit satellites to reduce space debris.

In the vast expanse of space, a small cable carries humanity’s dreams of exploring the universe and its safety bottom line. TST CABLE’s low-smoke halogen-free flame-retardant cables, seemingly ordinary, are indispensable “invisible heroes” in aerospace engineering. They don’t shine, yet they protect every ignition and launch; they don’t make a sound, yet they transmit the pulse between Earth and the stars.

Every leap forward in China’s aerospace industry is accompanied by its presence—light as a feather, strong as a shield, silent yet powerfully supporting the heavens.

Also available in:

English