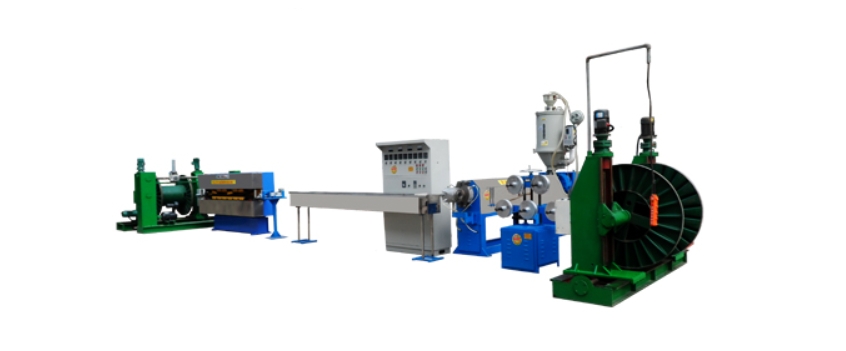

Extruder (Extruder) is mainly a machine used to produce plastic products such as wires and cables, pipes and profiles. It can melt, plasticize and mix the plastics through the pressure and heat generated by the rotation of the screw, and then extrude the plastics into the required shape through a specific mold. Extruders are widely used in the production of wires and cables, tubes, profiles, sheets, films and other fields.

In the wire and cable industry, the extruder is mainly used to produce the insulation layer and sheath layer of wire and cable. By melting and plasticizing the plastic material and then extruding it onto the wire conductor to form an insulating layer or sheath layer, it serves to protect the wire conductor and transmit current.

The main components of the extruder include screw, barrel, mold, heating system, transmission system and control system. Among them, the screw is the core component of the extruder, which is responsible for pushing the plastic material forward and generating pressure and heat to melt and plasticize the plastic. The barrel is the part that loads the plastic material, and the die is the part that extrudes the plasticized plastic into the desired shape. The heating system is used to provide the heat needed to melt the plastic, the drive system is responsible for the rotation of the screw, and the control system is used to control the operation of the entire extruder.

TST CABLES According to the different specifications and requirements of the extruded cables, the extruders can be generally categorized into 13 types.

Power cord and power cable extruder:

Mainly used for extruding power cords, insulated sheaths, power cables and other wires.

The composition of the equipment usually includes wire releasing machine, advocating force group, main machine, main control cabinet, cooling water tank, traction machine, spark machine, take-up machine and so on.

Material: usually used for PVC, PE and other conventional plastics.

Cable type: power line, power cable, etc.

Physical foam cable extruder:

Mainly used for all kinds of coaxial, communication, transmission lines and other low loss cable core extrusion, such as IEEE 1394, CATSE, CAT6, DVI, ATA, UL2919 and other cores.

It can be physically foamed or solid extruded, and is suitable for civil building wiring, nylon sheath extrusion.

Cable type: IEEE 1394, CATSE, CAT6, DVI, ATA, UL2919 and other low loss coaxial, communication, transmission line core wire.

Extruder for civil building wiring:

Extruders designed specifically for residential building cabling needs.

May include specific features or configurations to accommodate civil wiring standards and requirements.

Materials: May include PVC, PE, nylon, etc.

Cable types: BV, BVR, BVN, RV, nylon sheathed, etc. for residential wiring.

Nylon sheath extruder:

It is used for extruding nylon sheathing.

Nylon, as a commonly used engineering plastics, has a wide range of applications in the wire and cable industry.

Material: may include PVC, PE, nylon and so on.

Cable type: BV, BVR, BVN, RV, nylon sheathing and other civil building wiring.

Low smoke halogen free wire extruder:

Extruders specializing in the production of low-smoke halogen-free wires.

These wires produce less smoke and toxic gases when burning, and are suitable for occasions with higher safety performance requirements.

Cable types: low-smoke halogen-free electronic cables, computer cables, construction cables, data communication cables, and so on.

Chemical foam cable extruder:

Extruders that use chemical foaming technology to produce cables.

Chemical foaming technology improves the insulation and other physical properties of cables.

Cable types: communication, data, coaxial, RF, RG, JIS, HDMI, etc. Foamed core or solid core cables.

Silicone cable extruder:

Specialized in the extrusion production of silicone cables.

Silicone cables are widely used in special environments due to their excellent high temperature resistance, cold resistance and electrical properties.

Material: high temperature silicone.

Cable type: high temperature silicone cable and high temperature sleeve.

Teflon high temperature wire extruder:

Extruders for the production of Teflon (Teflon) high temperature wire.

Teflon high temperature wire has excellent high temperature resistance and electrical insulation properties.

Material: Teflon material.

Cable types: Teflon high temperature resistant wires, sleeves and thin-skinned insulated multi-layer cables.

Extruder for very fine wire coaxial cable:

Extruders specialized in the production of very fine wire coaxial cables.

Coaxial cables are widely used in the field of communications because of their good signal transmission properties.

Cable Type: Extremely Fine Coaxial Wire.

Extruders for digital communication network cables:

Extruders designed for the production needs of digital communication network cables.

These cables are typically used for high-speed data transmission and communication network construction.

Cable type: Digital network communication cables such as CAT5, CAT5E, CAT6A, CAT7, etc.

Extruder for secondary overmolding of TV optical fiber:

Extruder for secondary overmolding process of optical fiber.

Sleeving is an important process in the manufacture of optical fibers, used to protect optical fibers and improve their mechanical properties.

Material: It may involve the secondary overmolding material of optical fiber, cable-forming material and so on.

Cable Type: It is suitable for the secondary overmolding of TV optical fiber, cable formation of optical fiber, as well as the production of skin cable and municipal optical cable respectively.

TV optical fiber cable forming and extruding machine:

Extruding machine focusing on fiber optic cable formation process.

Cable forming is the process of combining multiple optical fibers or wires into a single cable to improve the overall performance and ease of use of the cable.

Extruder for Leatherline Fiber Optic Cables and Municipal Fiber Optic Cables:

Extruders for the production of fiber optic skin cable and indoor fiber optic cable.

Leather fiber optic cables and utility cables are two types of fiber optic cables commonly used in communication networks, and are suitable for different application scenarios.

Precautions for the operation of the extruder

Safety precautions:

Before operation, please make sure that all safety protection devices are intact, and it is strictly prohibited to remove, damage or short-circuit wiring without authorization.

Operators must wear labor protection equipment, including but not limited to safety helmet, protective glasses, earplugs and gloves.

Equipment Inspection and Preparation:

Before operation, please check whether the required raw materials, auxiliaries and formulas are adequately prepared and fill in the corresponding record sheet.

Check whether all parts of the extruder are in normal working condition, including but not limited to power supply, machine head, screw, heating ring, etc.

Operation standardization:

Before turning on the extruder, make sure that the corresponding power switch of the extruder is off, and then turn on the power.

During the operation, always pay attention to the running status of the extruder, including observing the rotation of the screw, the flow status of the melt and the appearance quality of the products.

It is strictly prohibited to adjust or disassemble the relevant parts during the operation of the machine to prevent accidents.

Abnormal situation handling:

In case of abnormal operation of the equipment, operator’s discomfort, power failure and disconnection or other unexpected situations, please stop the equipment operation immediately and take corresponding measures.

After the equipment stops, it should be cleaned and purged inside the equipment according to the process requirements to ensure the quality of the product at the next start-up.

Finishing work after operation:

After stopping the operation of the equipment, turn off all power and water sources inside the extruder, and clean up the working area to ensure that there are no sundries around the equipment.

Fill in the operation record form and report the operation of the equipment and the production of the products to the supervisor.

Safety Instructions:

Unauthorized personnel are prohibited from operating the Extruder, only trained and authorized personnel are allowed to operate the equipment.

Operators should familiarize themselves with the functions of each part of the extruder and how to use it, strictly follow the operation procedures, and should not change the working parameters or carry out non-specified operations without authorization.

It is strictly prohibited to wear gloves and other loose objects when operating the extruder to prevent accidents caused by the machine.

TST CABLES is the world’s leading manufacturer of high temperature cables.

TST CABLES has the world’s top cable equipment, not only leading technology, but also safety, efficiency and stability, TST CABLES cable extruder series, from power cord to fiber optic cable, comprehensive coverage, to meet your one-stop needs. Adopting advanced physical and chemical foaming technology, TST CABLES cable extruders ensure excellent quality, low loss and high performance of cable cores.TST CABLES equipment is adaptable to a wide range of materials, whether it is PVC, PE, nylon, silicone, Teflon, can easily cope with the TST CABLES team of professionals to provide a full range of technical support, to ensure that your production line is safe, efficient, and stable operation. Choosing TST CABLES is to choose the double guarantee of quality and strength, TST CABLES, make cable manufacturing and application safer!

TST CABLES–Specializing in high temperature resistant cable applications and solutions

Fluoroplastic Cables|Polyimide (PI) Cables|Polyetheretherketone (PEEK) Cables|Silicone Rubber Cables

Rail way | Aviation | Marine | Nuclear | Oil & Gas | Wind Power industry applications

For more information on EN 50264 cables,low-smoke, halogen-free, flame-retardant, high-temperature-resistant cables or to customize cables for your machinery or system, visit https://www.tstcables.com/contact-us/

or send an e-mail to:lixiangchao@testeck.com.

Also available in:

English