Introduction:

• LSZH is the short form of Low Smoke Zero Halogen.

• These cables are constructed with jacket material free from halogenic materials such as chlorine and fluorine as these chemical have toxic nature when they are burned.

• LSZH cables are used mainly in Europe.

• It is used in shipboard applications and computer networking rooms where toxic or acidic smoke and fumes can injure people and/or equipments.

• Examples of Halogens include fluorine, chlorine, Bromine and Iodine.

• These materials when burned produce acidic smoke that can cause harm.

• These cables will self extinguish.

•They are used where people are very near to cable assemblies where they do not get adequate amount of ventilation in the event of fire or there is poor ventilated areas.

Following are the benefits or advantages of LSZH cable:

•They are very cost effective.

•They are used in railway systems where high voltage signal wires are used in underground tunnels. This will reduce possibilities of accumulation of toxic gases when cables get fire.

•They are constructed using thermoplastic compounds which emit limited smoke with no halogen.

•They do not produce dangerous gas when they come in contact with high sources of heat.

•LSZH cable jacket helps in protection of people in the event of fire, smoke and dangerous gas due to burning of cables.

Following are the drawbacks or disadvantages of LSZH cable:

•LSZH cable’s jacket uses high % of filler material in order to offer low smoke and zero halogen. This makes jacket less chemical/water resistant compare to non-LSZH cable counterpart.

•Jacket of LSZH cable experiences cracks during installation. Hence special lubricants are needed to prevent it from damage.

•It offers limited flexibility and hence it is not suitable for robotics.

If protection of equipment or people is a design requirement, consider low-smoke zero-halogen (LSZH) jacketed cables. They emit fewer toxic fumes than standard PVC-based cable jackets. Typically, LSZH cable is used in confined spaces such as mining operations where ventilation is of concern.

What is the difference between LSZH cable and common cables?

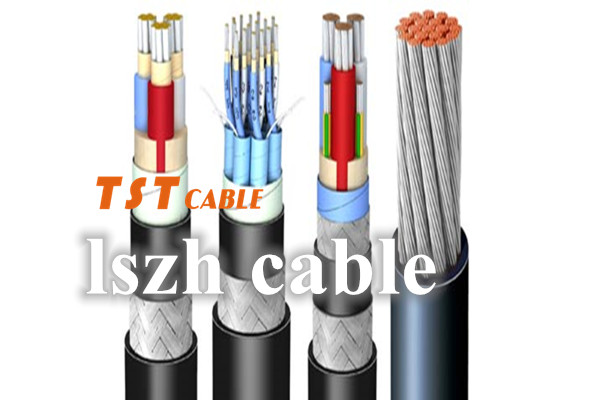

The function and technique parameter of LSZH fiber optic cable is just like common fiber optic cables, and inner structure is also similar, the basic difference is the jackets. LSZH fiber optic jackets is more fire-resistant compared with common PVC jacketed cables, even when they are caught in fire, the burned LSZH cables provide low smoke and no halogen substances, this feature is not only environment protective but the low smoke when it got burned is also important to people and facilities in the fired place.

LSZH jacket is made up of some very special materials which are non-halogenated and flame retardant. LSZH cable jacketing is composed of thermoplastic or thermoset compounds that emit limited smoke and no halogen when exposed to high sources of heat. LSZH cable reduces the amount of harmful toxic and corrosive gas emitted during combustion. This type of material is typically used in poorly ventilated areas such as aircraft or rail cars. LSZH jackets are also safer than Plenum-rated cable jackets which have low flammability but still release toxic and caustic fumes when they are burned.

Low smoke zero halogen is becoming very popular and, in some cases, a requirement where the protection of people and equipment from toxic and corrosive gas is critical. This type of cable is ever involved in a fire very little smoke is produced making this cable an excellent choice for confined places such as ships, submarines, aircraft, high-end server rooms and network centers.

Every coin has two sides. Since LSZH cables have so many benefits listed above, what are the Cons of the cable?

1. LSZH is more susceptible to jacket cracking. Special lubricants have been made to minimize damage during installation.

2. LSZH jacket has a high filler content, around 50% to provide the required flame and smoke performance. This results in a lower mechanical, chemical resistance, water absorption and electrical properties then non LSZH compounds.

3. The current generation of LSZH cables has not yet established a proven history of long time performance.

The LSZH cables are available with 1, 2, 12, 24 fibers, and variable sub-cable dimensions that support specific termination and routing requirements. They are suitable for halogen free and many international installations. LSZH cable contains no flooding gel and is OFNR Riser rated, is perfect for installation in conduits between buildings and run directly thru risers to a convenient network or dome fiber optic splice closure without a separate point of splice at building entrance.

There are also LSZH fiber optic patch cords available. Both LSZH fiber optic cables and LSZH fiber optic patch cords are required for the Rosh compliant cable assemblies, but Rosh standard is more strict besides it require the cables to be LSZH type. LSZH fiber optic jumper are used widely used in the places where expensive equipment would be damaged if exposed to corrosive gases, and they are also used in crowded areas like commercial centers and sports centers.

The European market is demanding that cables used in LANs, WANs, etc. meet LSZH specification. The IEC 60332-1 governs the Flame Retardant Grade specifications in reference to LSZH cables.Reduction of dangerous/poisonous gases

Essentially, the compound used in manufacturing cables meeting the above specification reduces the amount of dangerous/poisonous gases in case of fire. The main difference in specifications between IEC 60332-1 versus UL® 1581, UL 1666 and UL 910 is that the cable under the IEC spec can continue to burn while still emitting very low gases. The UL specs demand that the flame be extinguished, but it can still emit dangerous/poisonous gases.IEC specification

Today virtually all medium and large installations in Europe must meet the IEC specification. Many public authorities are already demanding that new installations must meet IEC 60332-3 which is a more demanding flammability specification for LSZH.

What’s the difference between PVC and LSZH cables

Physically, PVC and LSZH are very different. PVC patchcords are very soft; LSZH patchcords are more rigid because they contain the flame retardant compound, and they are aesthetically more pleasing

A PVC cable (made of polyvinyl chloride) has a jacket that gives off heavy black smoke, hydrochloric acid, and other toxic gases when it burns. Low Smoke Zero Halogen (LSZH) cable has a flame-resistant jacket that doesn’t emit toxic fumes even if it burns.

LSZH cables more expensive and less flexible

LSZH cables usually cost more than the equivalent PVC cable, and certain types are less flexible. LSZH cable does have some restrictions. According to CENELEC standards EN50167, 50168, 50169, screened cables must be halogen free. However, no similar regulation yet applies to unscreened cables.

Where do you run the cable?

Whether you choose a riser (PVC), plenum or LSZH jacket depends on where you’re going to run the cable.

PVC cable is commonly used for horizontal runs from the wiring centre. You can use it for vertical runs between the floors – but only if the building features a contained ventilation system running through the duct work.

LSZH cable is used between floors in a building. It has a special flame-retardant coating.

A plenum is a space within the building created by building components, designed for the movement of environmental air.

Also available in:

English